Pcb manufacturing

How to make your own photo pcbs.

My brother and I manufacture our own photo pcbs and it is not as difficult as it may seem at first. You will need a saw, a UV lightbox to expose, some chemicals to develop & etch and finally a drillingmachine.

Picture gallery:

Click on the picture to enlarge it and read our comments and advice

Previous image

Next image

Back to overview

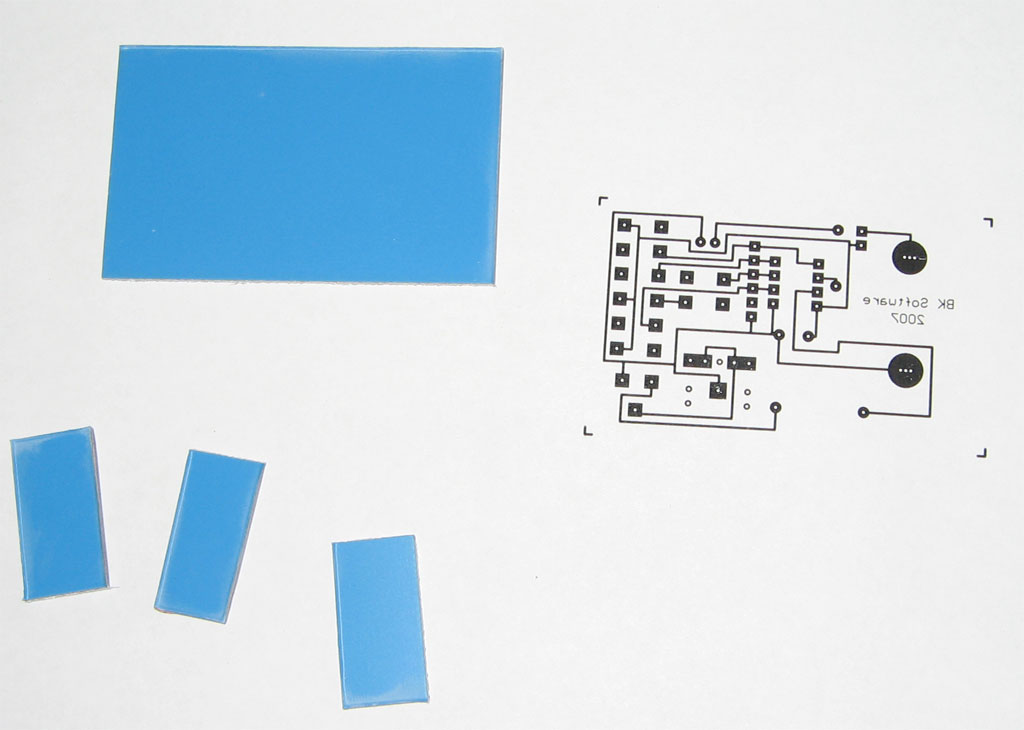

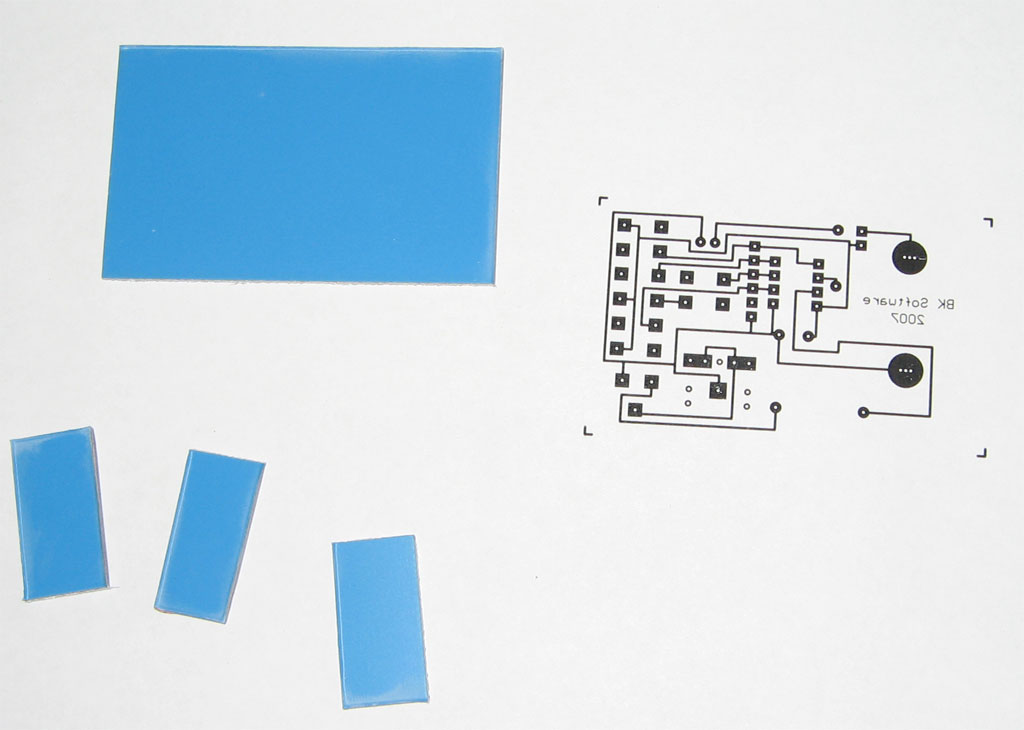

Here is the sawed pcb. We use Bungard positive photopcb because we have very good experience with it. Notice that we have also cut three small trial pcbs to test the strenght of the developer.